Comparison table of advantages and disadvantages of vertical and horizontal powder coating lines for

Line type | Horizontal powder coating line | Vertical Powder Coating Line | |

Conveyor | Ordinary chain | Power and free chain | Closed track hanging chain |

Typical annual production/t | 4000-800 | 4000-8000 | 12000-30000 |

Typical footprint/m² | 1200 (without pretreatment) | 400 (without pretreatment) | 1200 (without pretreatment) |

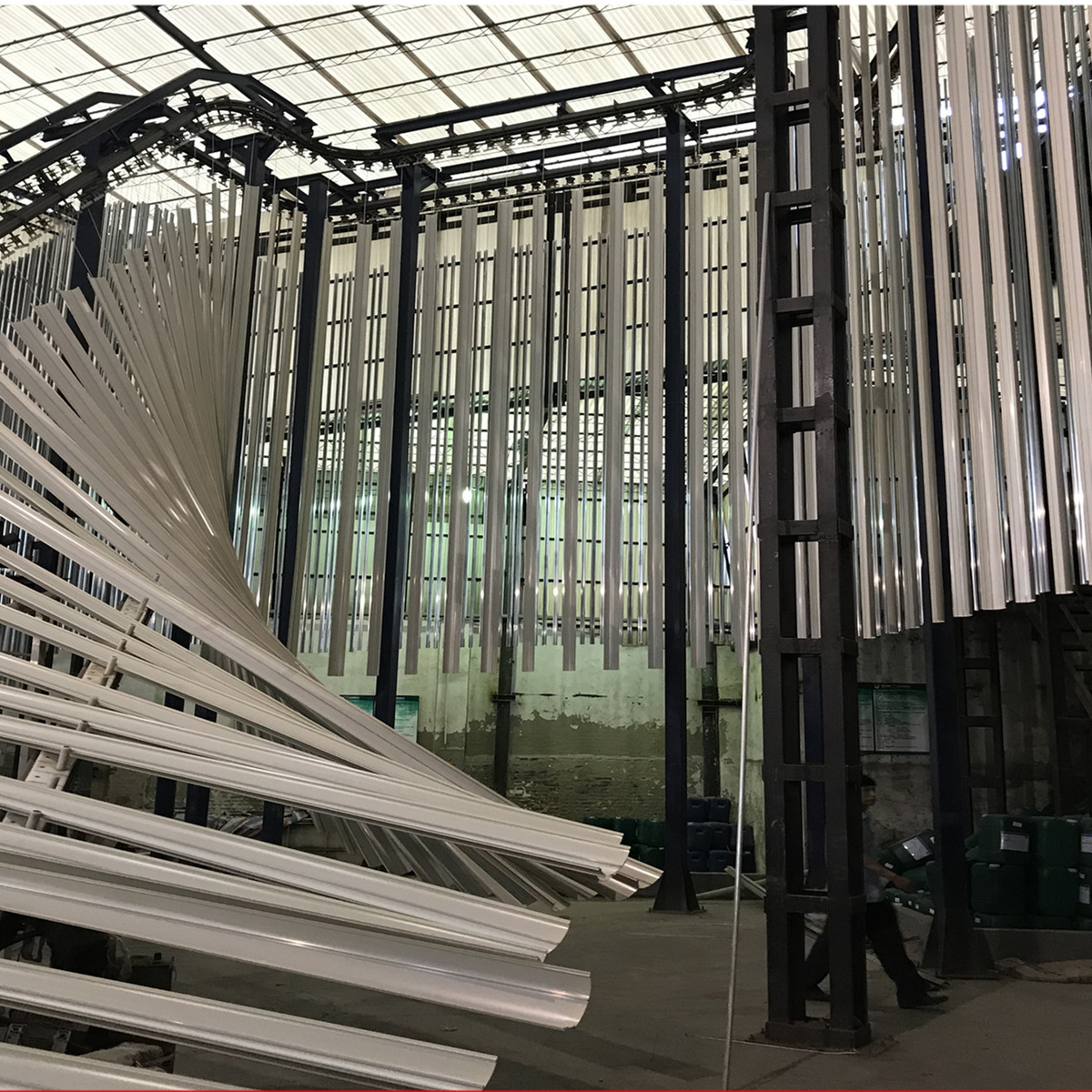

Advantages | 1. The structure of conveyor chain is simple and easy to maintain; 2. Hanger pitch can be flexibly adjusted according to the length of aluminum profiles | The conveyor consists of a traction track and a load-bearing track, which can branch, detach, transfer and store aluminum profiles, thus, making the curing oven, loading and unloading areas have a large footprint. | 1. Pretreatment- powder spraying- curing in one, high degree of automation, in the case of the same chain speed and covers an area of roughly the same, the output is 4-5 times that of the horizontal line; 2. Good liquid dripping of pre-treatment, less chemical and water consumption; 3. In the spray booth, the aluminum profile can be rotated by 4×90°. |

Disadvantages | 1. Large floor space, low output per unit area; 2. Long curing oven, high energy consumption per unit output; 3. It is difficult to set up a continuous production line with the pre-treatment group, requiring more production workers; 4. Large film thickness difference of aluminum profiles, generally up to ±20μm; 5. Higher operating costs due to higher energy consumption, chemical consumption, powder consumption and labor cost. | 1. Requires a high level of maintenance for the transporter. 2. It is difficult to set up a continuous production line with the pre-treatment group, requiring more production workers; 3. Large film thickness difference of aluminum profiles, generally up to ± 20μm; 4. Higher operating costs due to higher energy consumption, chemical consumption, powder consumption and labor cost. | 1. Large initial investment in equipment; 2. Requires better management |

Typical consumption | Degreasing agent: 6kg Chromating agent: 4kg Water consumption: 10t Powder consumption: 45kg Oil consumption: 80kg Electricity consumption: 180kW▪h | Degreasing agent: 6kg Chromating agent: 4kg Water consumption: 10t Powder consumption: 45kg Oil consumption: 70kg Electricity consumption: 60kW▪h | Degreasing agent: 3kg Chromating agent: 3kg Water consumption: 4t Powder consumption: 38-40kg Oil consumption: 80kg Electricity consumption: 50-60kW▪h |

ours@yzours.com

ours@yzours.com